Vital Kitting & Assembly

Automated & Manual

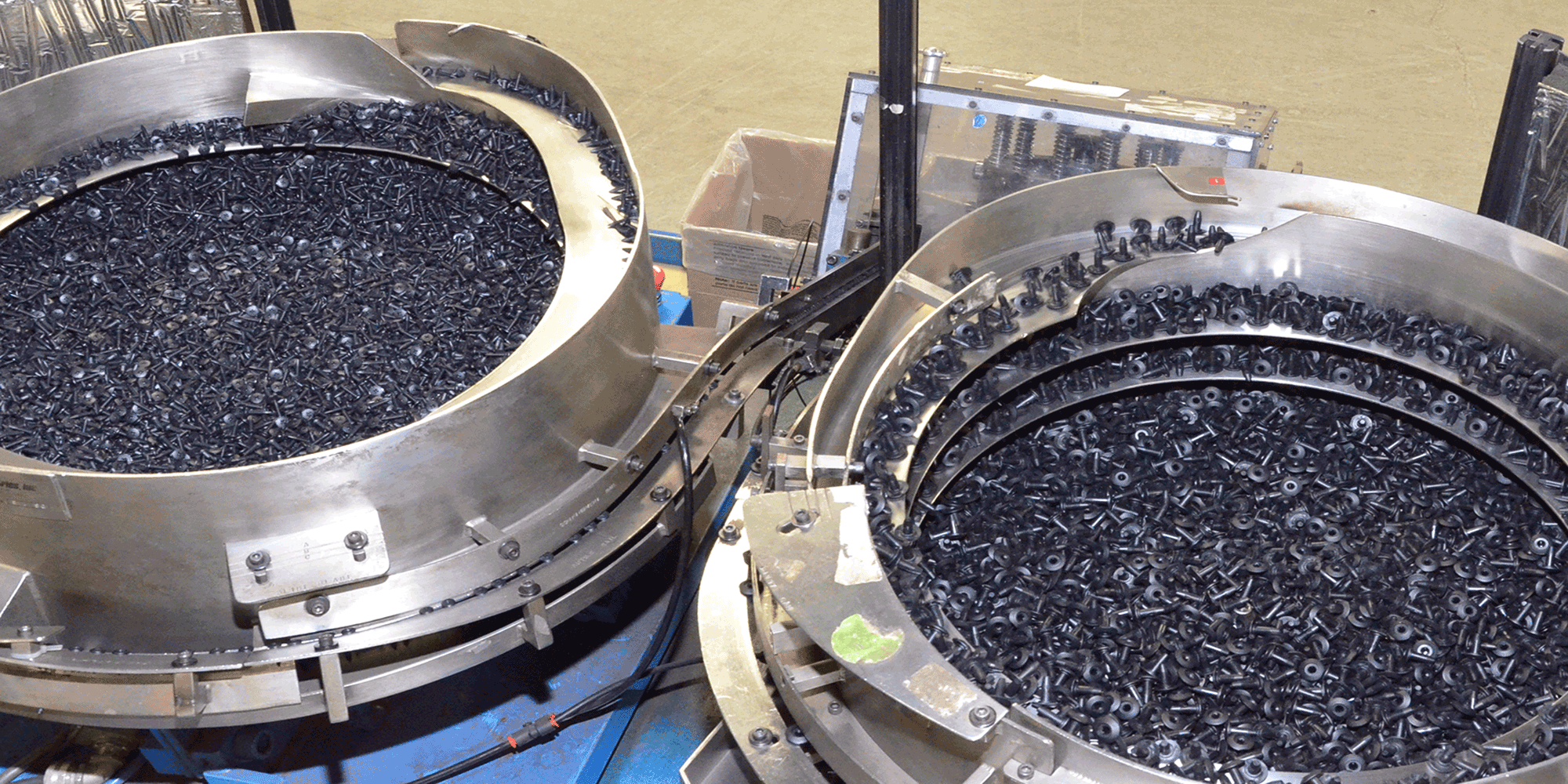

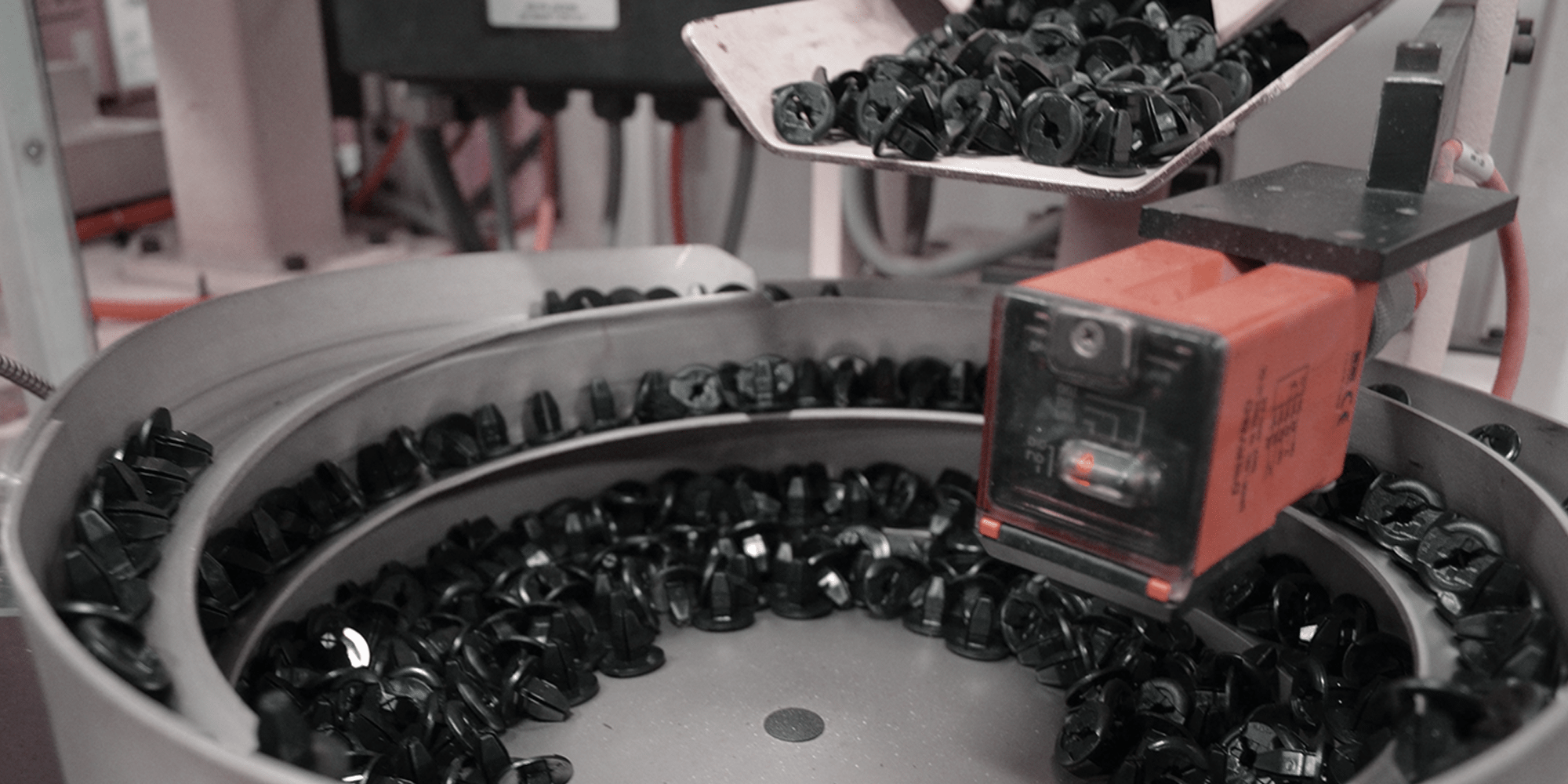

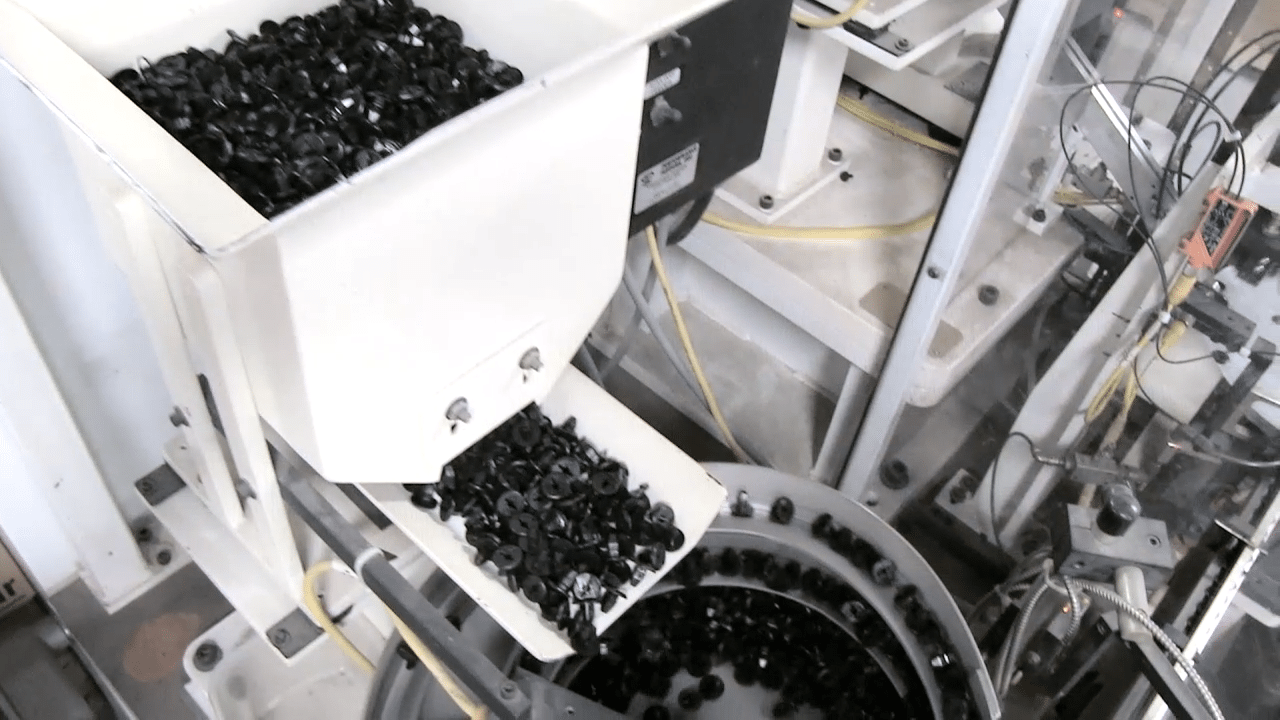

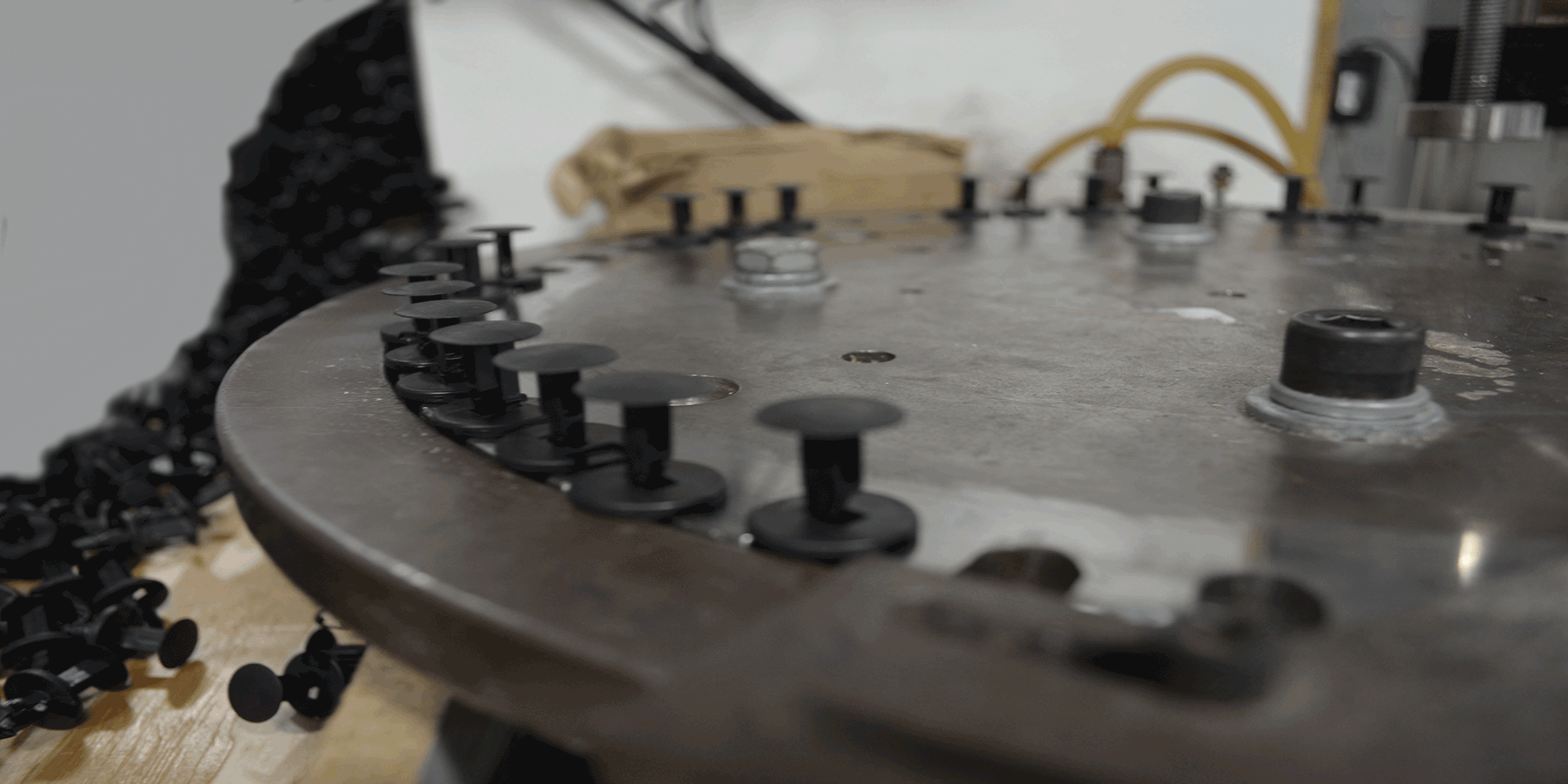

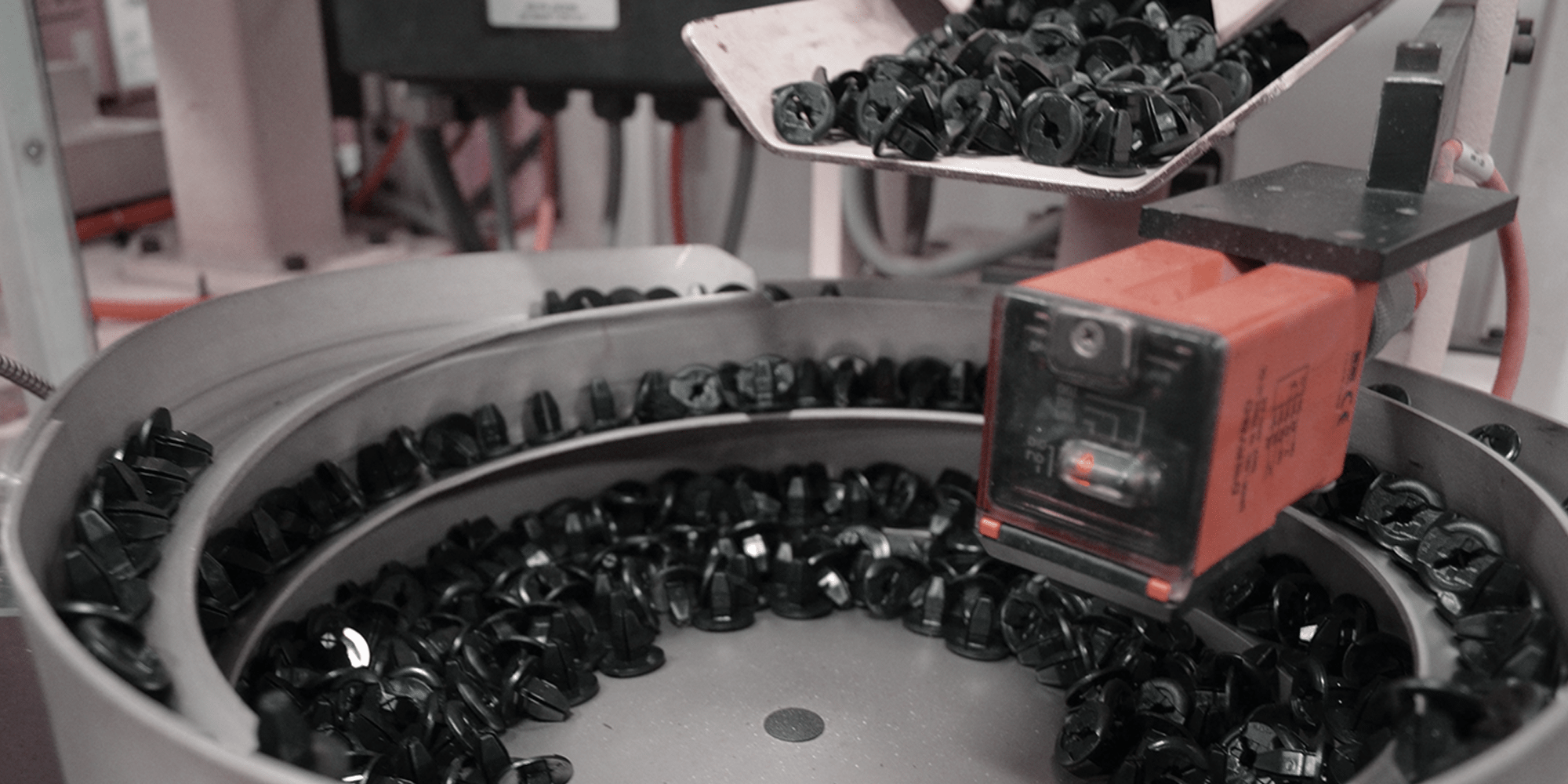

The capacity of our facility allows us to utilize kitting services and optimize the production process for large volume assembly and complex secondary operations. We utilize fully-automated and semi-automated assembly machines and our program of hand assembly employs the skill of more than 200 at-home workers. This facilitates the assembly of basic, multi-component products with high-quality and a competitive rate.

Integrated Solutions

Vital Plastics ability to work with your engineering team and integrate our operations with yours is the core of our business in our kitting services. We utilize fully-automated and semi-automated assembly machines and we also run customer supplied equipment. In cases where the volume doesn’t warrant the expense of fully automated machines, we’ll utilize our semi-automatic equipment or hand-set assembly as additional options.

Kitting & Assembly Solutions

Our large volume kitting & assembly services eliminate the need for additional vendors in your supply chain by providing single source & cost-effective solutions.

Integration With Your Manufacturing

Through Engineering, Collaboration & Innovation

Secondary Operations

Our secondary and specialty operations grant us the opportunity to manage simple to complex assembly services. These are vital solutions that we can integrate within your current manufacturing processes and supply high-quality parts.

We have shipped over 700 million large volume assemblies with less than 41 DPPM (Defective Parts Per Million) over the past eight years.

Automated & Semi-Automated

Ultra-Sonic Welding

Pad Printing

Hot-Stamping

Kitting

Specialty Packaging

The Vital Differences

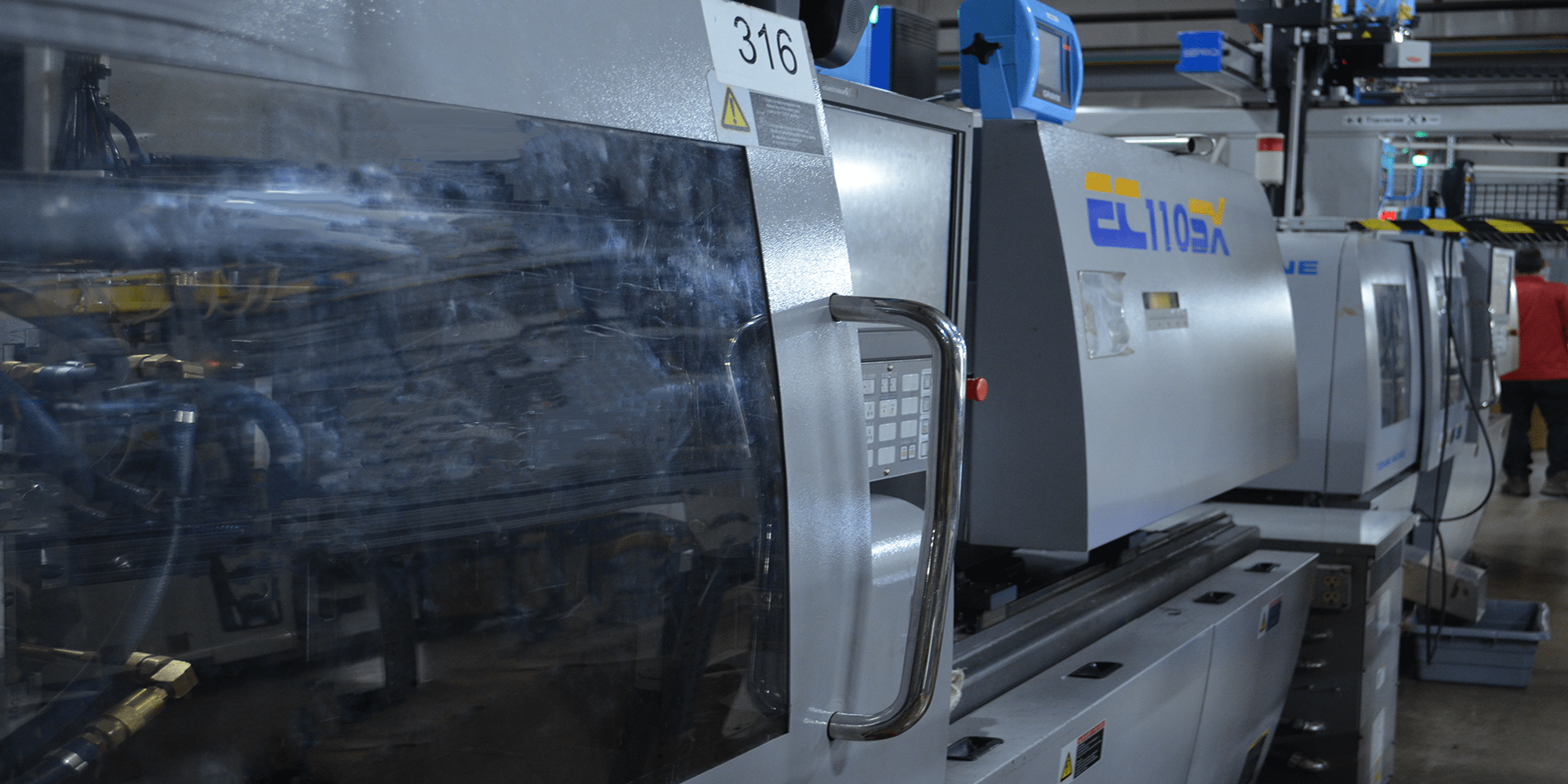

INJECTION MOLDING

With Over 56 injection molding machines ranging from 30 Tons – 400 Tons, Vital Plastics has the capabilities, engineering resources, and technology to become your premier supply-chain partner.

ASSEMBLY OPERATIONS

We focus on providing the most comprehensive post-molding & value-added services available to our customers. Whether it’s a fully-automated, semi-automated or hand assembly/kitting, we are dedicated to providing our customers with more than just injection molding capabilities.

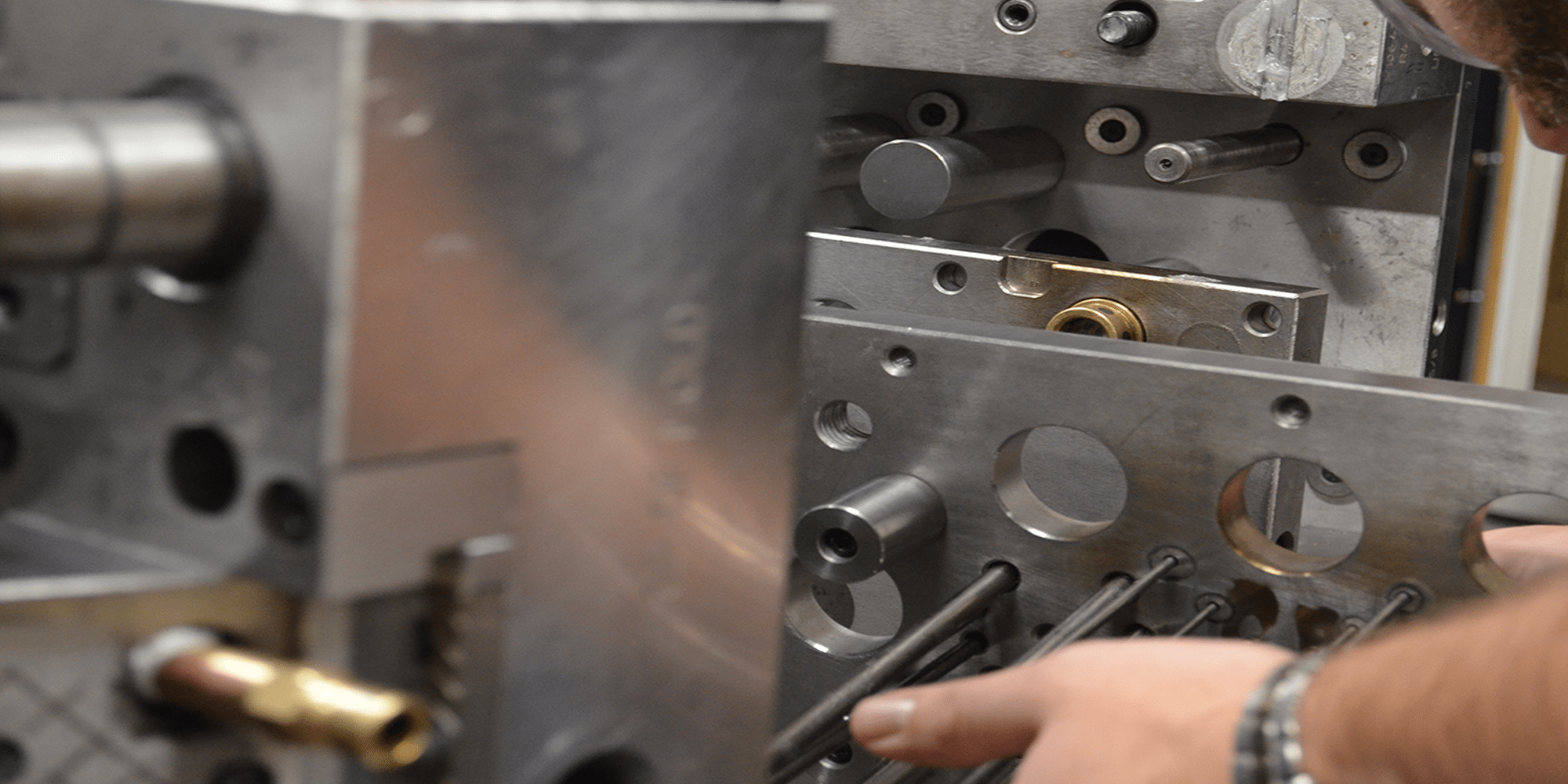

TOOLING SOLUTIONS

From simple rev changes to new tooling projects, we have the capabilities and resources to handle the most complex injection molded parts. Additionally, our off-shore partnerships can provide cost effective tooling solutions, depending on the project.

SUPPLY-CHAIN SOLUTIONS

Looking for a new Partner? Look no Further!