What makes us VITAL

Our custom injection molding solutions are just a piece of our success. Our engineers and support team is what truly separates us.

We are more than just a molder…..From prototypes to production, our number one goal is to exceed your injection molding & assembly requirements. With more than 250 people on our assembly team, we have the capacity to handle the largest assembly projects with various requirements from fully-automatic, semi-automatic or hand-set assemblies.

With our two manufacturing facilities we are the perfect size, we’re large enough to handle your high volume molding & assembly needs, yet small enough for us to focus on each customer’s needs. At Vital Plastics, our goal is to help unclutter your manufacturing floor – resulting in greater yields. We look forward to being your manufacturing partner on your journey to improve your efficiencies and your profitability.

Our Value

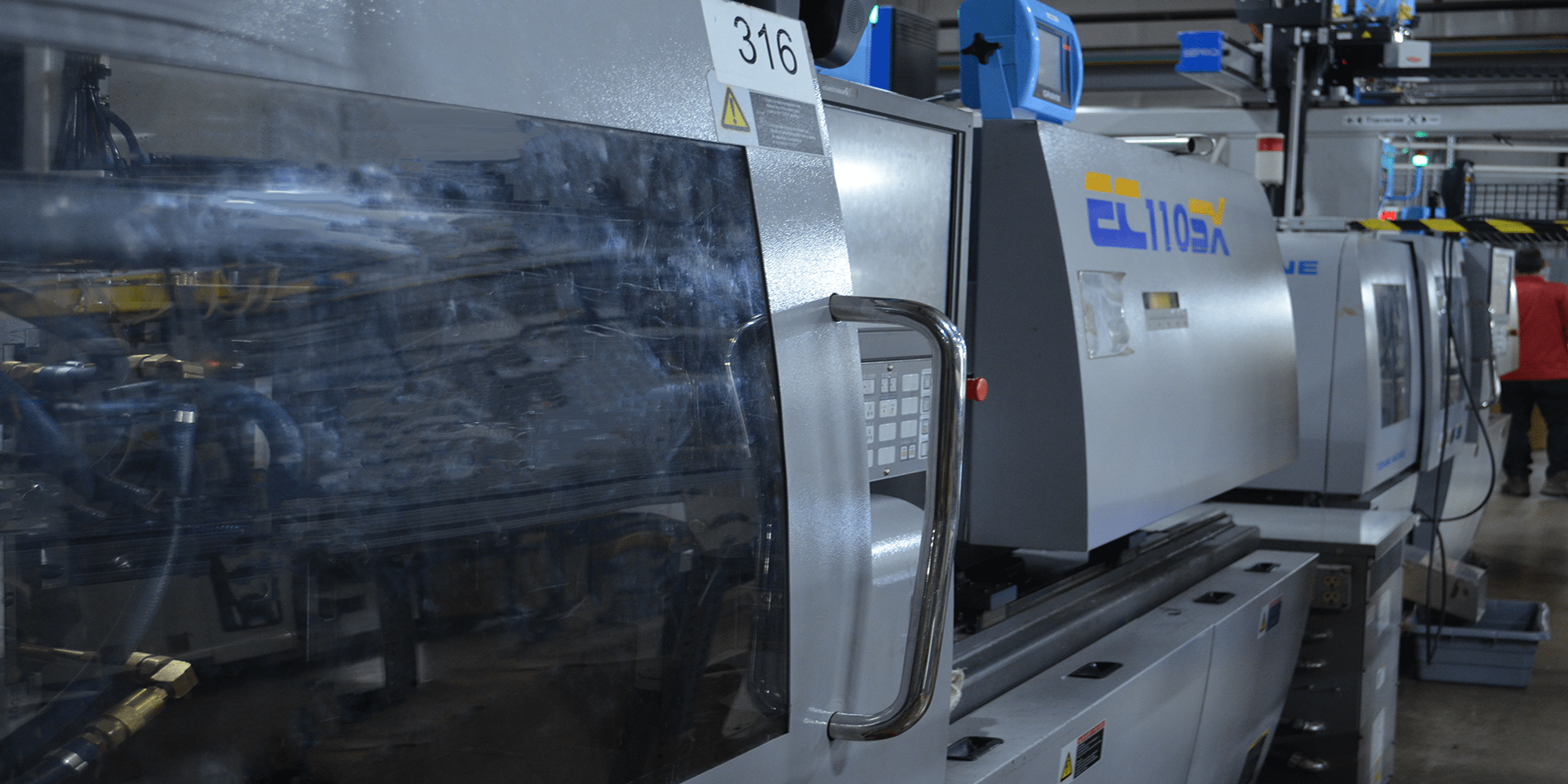

Strategically located East of Minnesota’s Twin Cities metro area on Interstate I-94, Vital Plastics, Inc. is an industry leader in Thermoplastic Injection Molding and Contract Assembly. Since 1994, Vital Plastics is focused on providing above and beyond customer service, design & engineering assistance, and quality parts, on-time. With nearly 70,000 sq. ft. of climate controlled manufacturing space, and an additional 6 acres of land for future growth, no project is too big or too small for our team to handle. We utilize all-electric injection molding machines, for process efficiency and consistency, ranging in size from 30T to 400T.

OUR STRENGTHS

Not just another molder…we are pushing the supply chain standards and raising the bar for other molders to be held to. As technology continues to evolve, Vital Plastics is at the front line of implementing the most efficient and effective solutions to excel in all areas of custom injection molding. Our well rounded services and support resources provide our customers with best in class supply chain solutions and the highest quality.

Integration With Your Manufacturing

Through Engineering, Collaboration & Innovation

The Vital Team

The Vital Differences

INJECTION MOLDING

With Over 56 injection molding machines ranging from 30 Tons – 400 Tons, Vital Plastics has the capabilities, engineering resources, and technology to become your premier supply-chain partner.

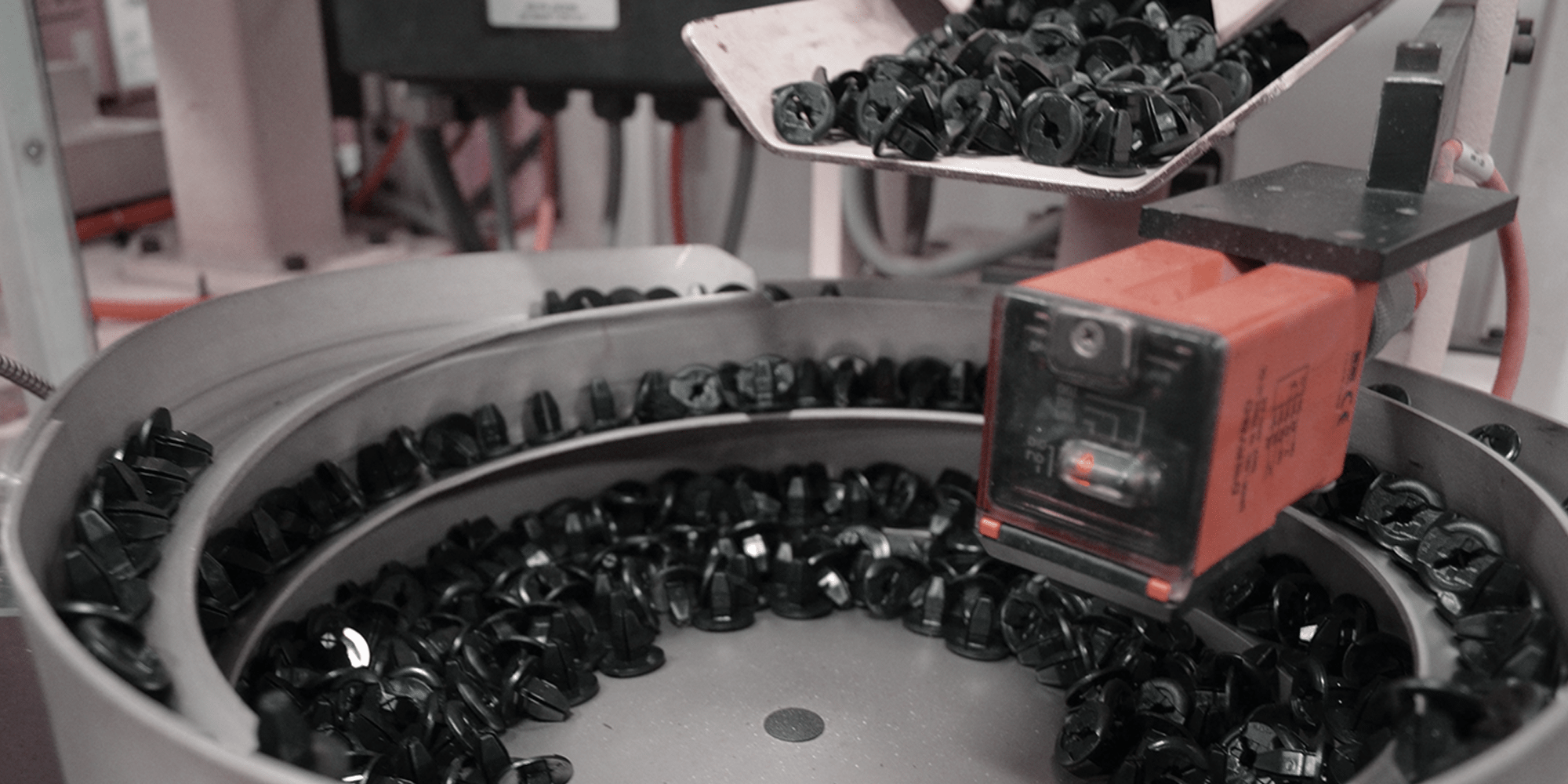

ASSEMBLY OPERATIONS

We focus on providing the most comprehensive post-molding & value-added services available to our customers. Whether it’s a fully-automated, semi-automated or hand assembly/kitting, we are dedicated to providing our customers with more than just injection molding capabilities.

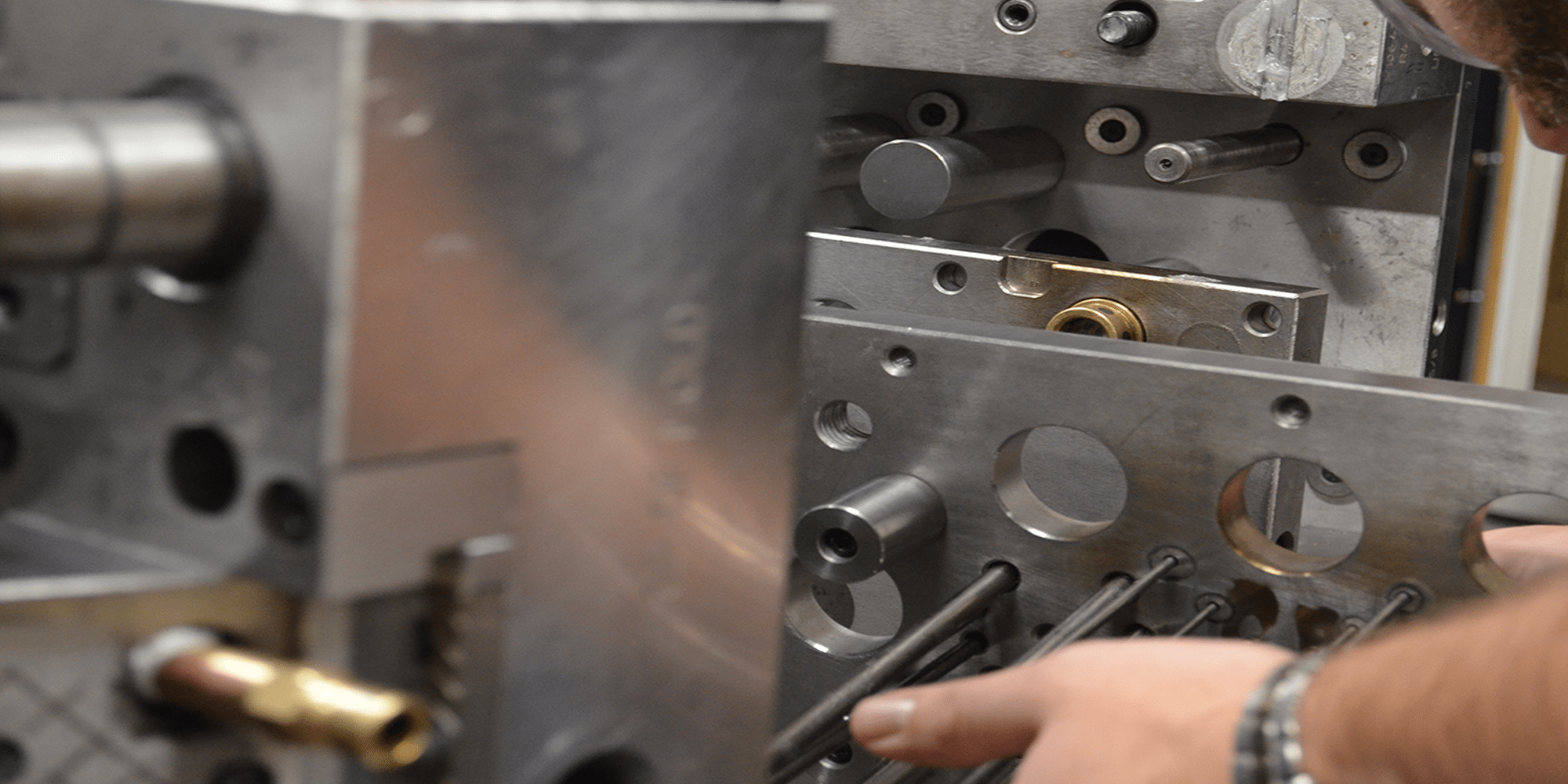

TOOLING SOLUTIONS

From simple rev changes to new tooling projects, we have the capabilities and resources to handle the most complex injection molded parts. Additionally, our off-shore partnerships can provide cost effective tooling solutions, depending on the project.

SUPPLY-CHAIN SOLUTIONS

Looking for a new Partner? Look no Further!