Custom Injection Molding Solutions

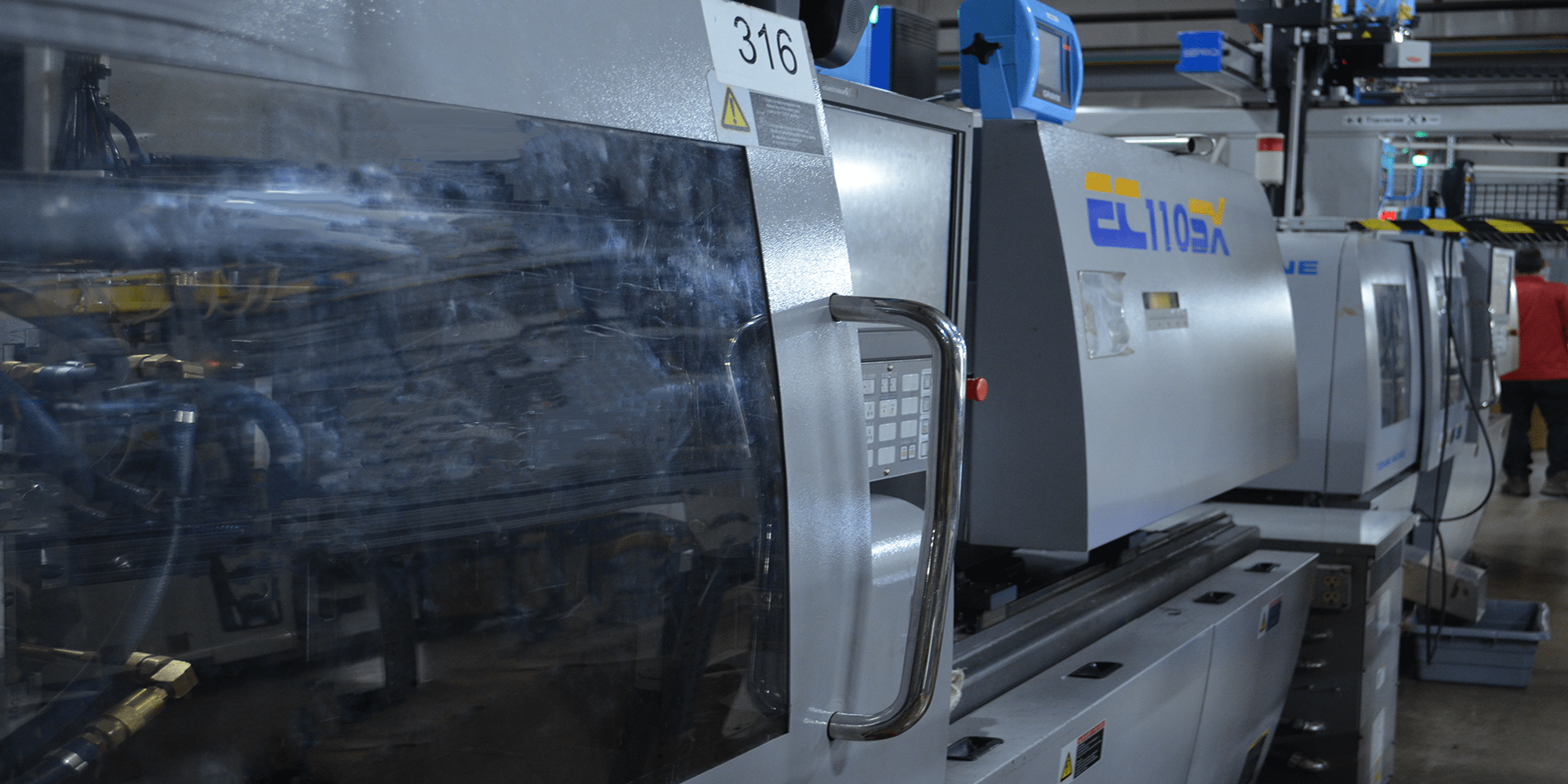

With over 56 plastic injection molding machines ranging from 30 tons to 400 tons, we operate 24 hours per day and 7 days per week in order to meet our customer’s needs. Offering a wide range of custom injection molding solutions serving a variety of strategic markets, Vital Plastics has been focused around providing customers with a comprehensive solution to their plastics needs. As technology and markets continue to evolve we stay committed to reinvesting back into our infrastructure and expanding our resources so we can always provide the best available value in the custom injection molding supply chain. Whether our customers have simple shoot and ship type of products or comprehensive assembly & value-add opportunities; we welcome the opportunity to showcase our extensive engineering and technology services.

Our Markets

Automotive / Transportation

Industrial

Agriculture

Appliance

Consumer Goods

Electronics / Telecommunications

Custom Injection Molding Capacity

When you combine our molding capabilities with our engineering solutions the possibilities are endless. Our seamless integration into your systems also provides the additional support you need. From prototype to production we are here to see the finished product shipped directly to you.

- 30 Tons to 400 Tons

56 molding presses

Integrated Automations

Vertical Entry Robotics On Machines

Scientific Molding Approach

IQMS ERP System

Solidworks Flow Simulation

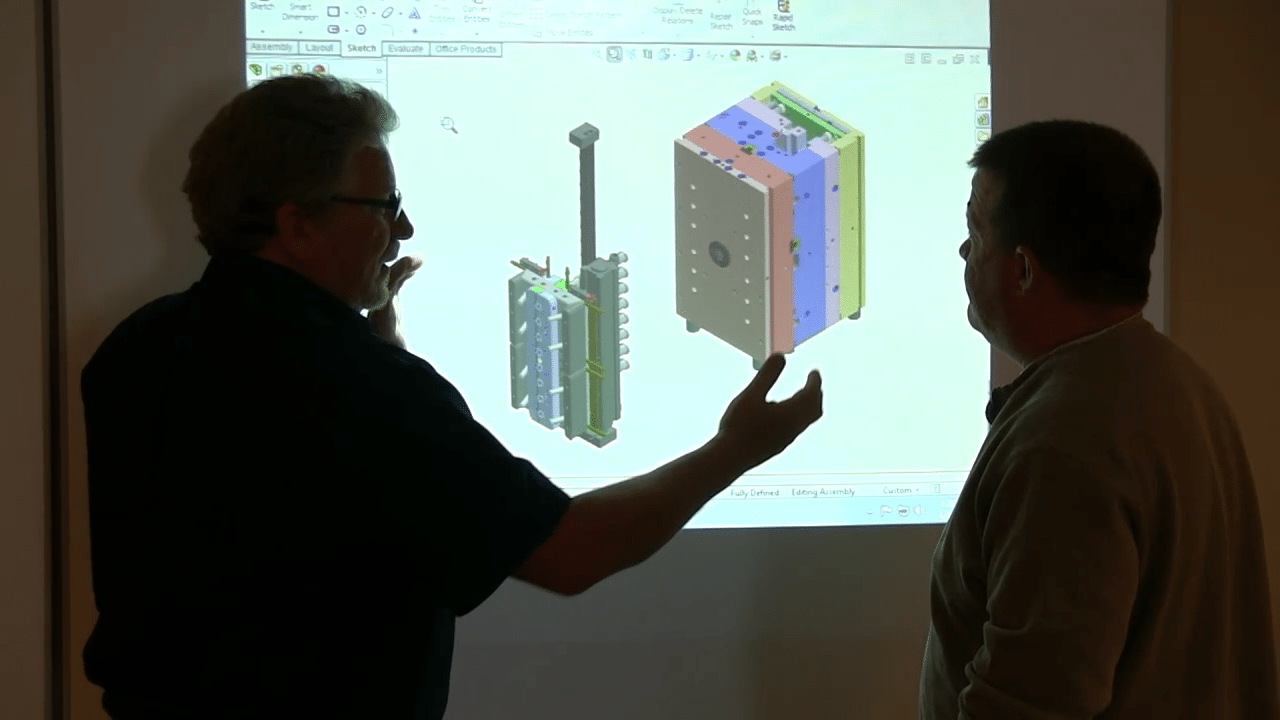

Engineering Services

When you combine our molding capabilities with our engineering solutions the possibilities are endless. Our seamless integration into your systems also provides the additional support you need. From prototype to production our Engineering Team is here to see that a quality finished product is shipped directly to you, on-time, every time.

From the initial integration into our system and being assigned a dedicated project engineer, we begin providing a comprehensive array of engineering expertise in plastics. By utilizing the latest technology for plastics flow simulation software, our Design For Manufacturability (DFM) process is hands down some of the best in the industry. With completing a full analysis of the products geometry, we are able to uncover significant opportunity for part design improvements that typically either reduce overall costs or increase the efficiency during the production process.

Our Engineering Team has over 25+ years of experience in custom injection molding, and we protect all of our clients from costly mistakes that are identified during the early stages of development.

DFM Analysis

Solidworks Flow Simulation

Tool & Part Design Review

Warpage Analysis

Gate Location Analysis

Dedicated Project Engineer

Finite Element Analysis (FEA)

Material Recommendation

Integration With Your Manufacturing

Through Engineering, Collaboration & Innovation

Scientific Molding

We utilize a Scientific Approach to molding, which is vastly different than most of our competitors. With the scientific molding mindset, we are developing a more robust and stable process that in turn reduces the total scrap percentage and quality defects. Beginning during the design phase and using our internal DFM process, we analyze every aspect of the manufacturing process to ensure that when production begins the process will be the most efficient and repeatable.

Our Master Molder Certified Process Engineers’ utilize Scientific Molding principles in order to ensure full-control over processing variables, ensuring the delivery of perfect parts, on-time.

Increased Efficiency & Throughput

Data Backed Decision Making

Master Molder Certified Process Engineers

Robust Process Control

The Vital Differences

INJECTION MOLDING

With Over 56 injection molding machines ranging from 30 Tons – 400 Tons, Vital Plastics has the capabilities, engineering resources, and technology to become your premier supply-chain partner.

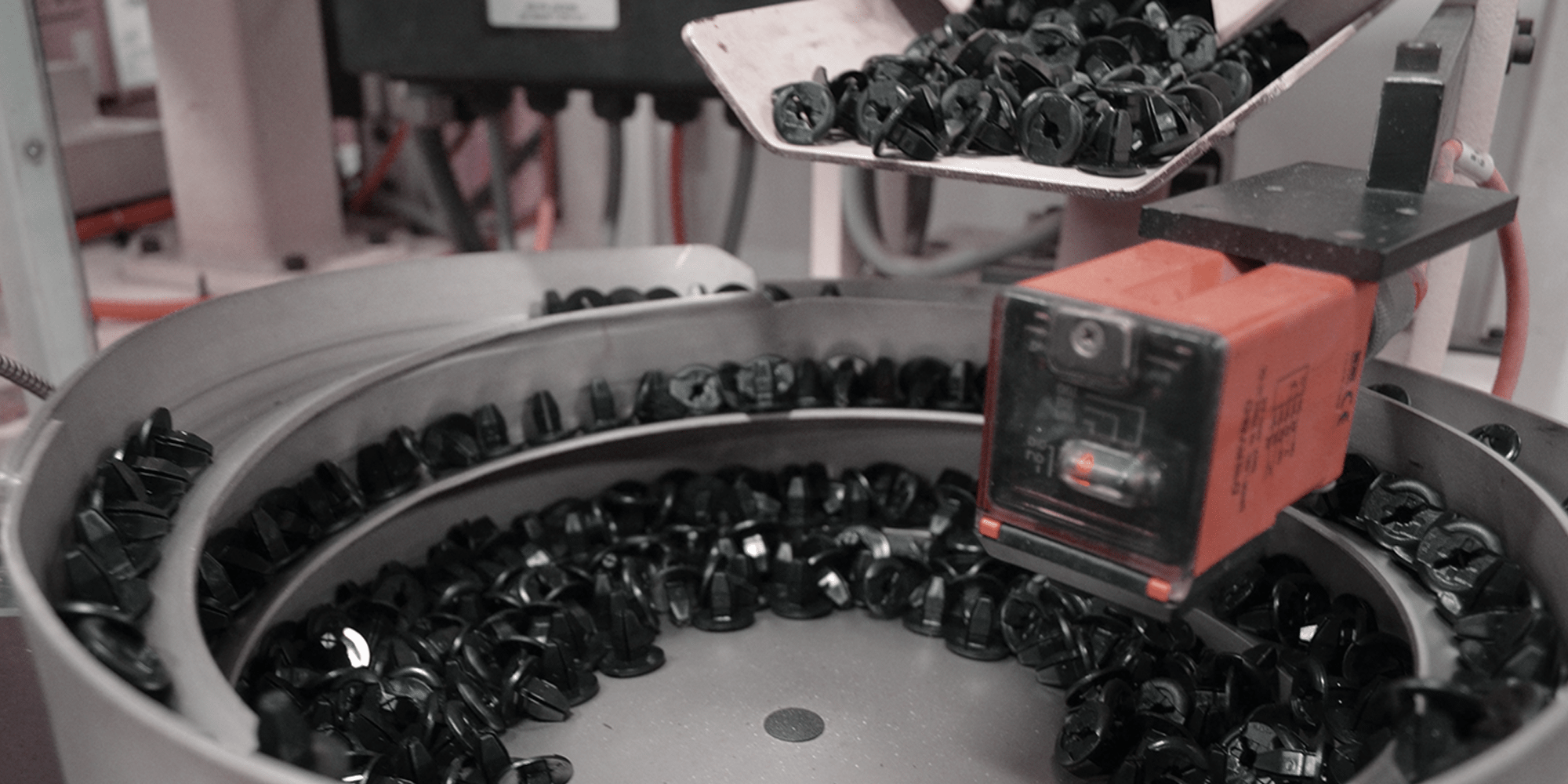

ASSEMBLY OPERATIONS

We focus on providing the most comprehensive post-molding & value-added services available to our customers. Whether it’s a fully-automated, semi-automated or hand assembly/kitting, we are dedicated to providing our customers with more than just injection molding capabilities.

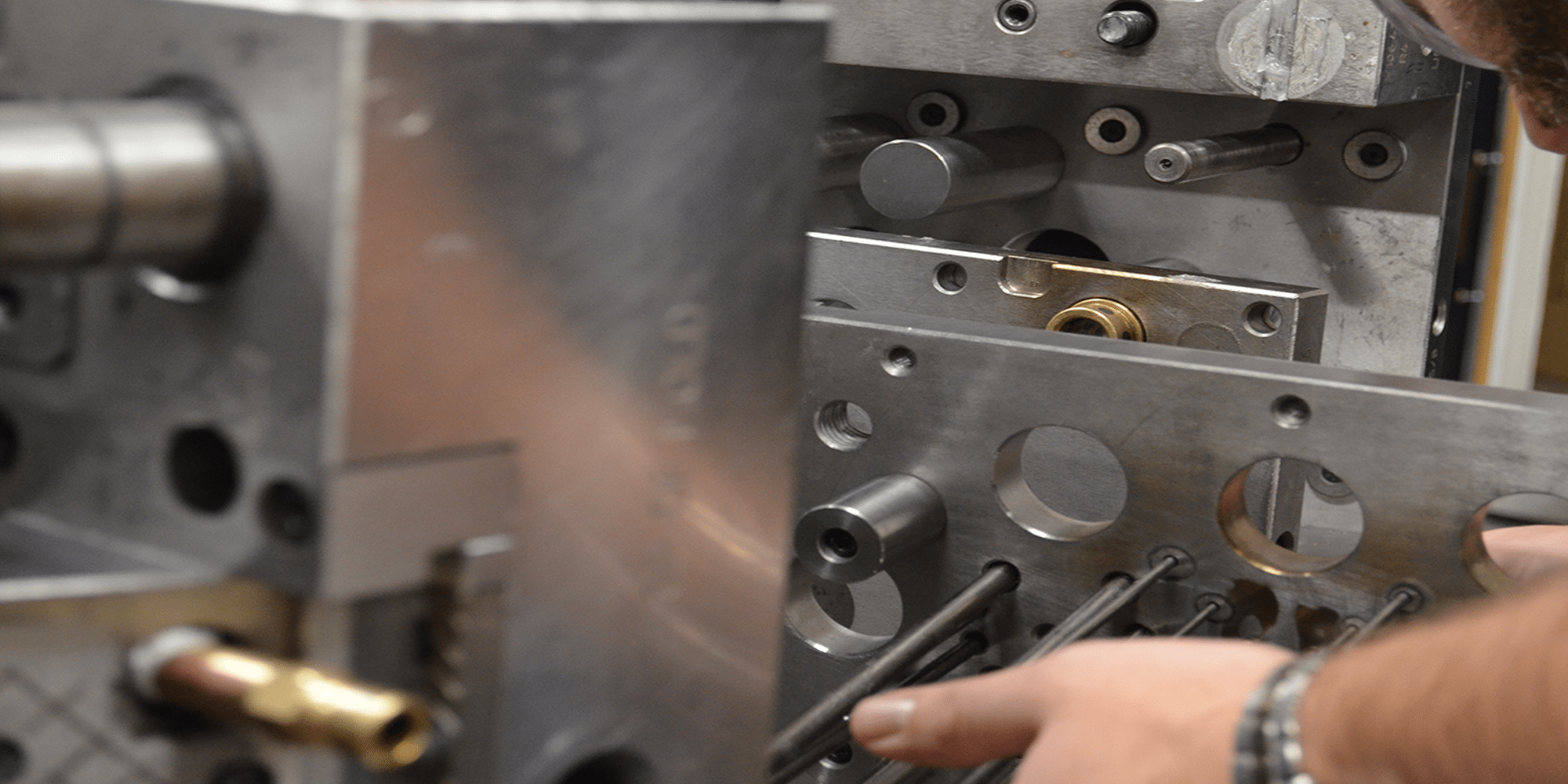

TOOLING SOLUTIONS

From simple rev changes to new tooling projects, we have the capabilities and resources to handle the most complex injection molded parts. Additionally, our off-shore partnerships can provide cost effective tooling solutions, depending on the project.

SUPPLY-CHAIN SOLUTIONS

Looking for a new Partner? Look no Further!